We are suppliers of earthing equipment for road tankers and other specialized products used to monitor and control safety in hazardous areas.

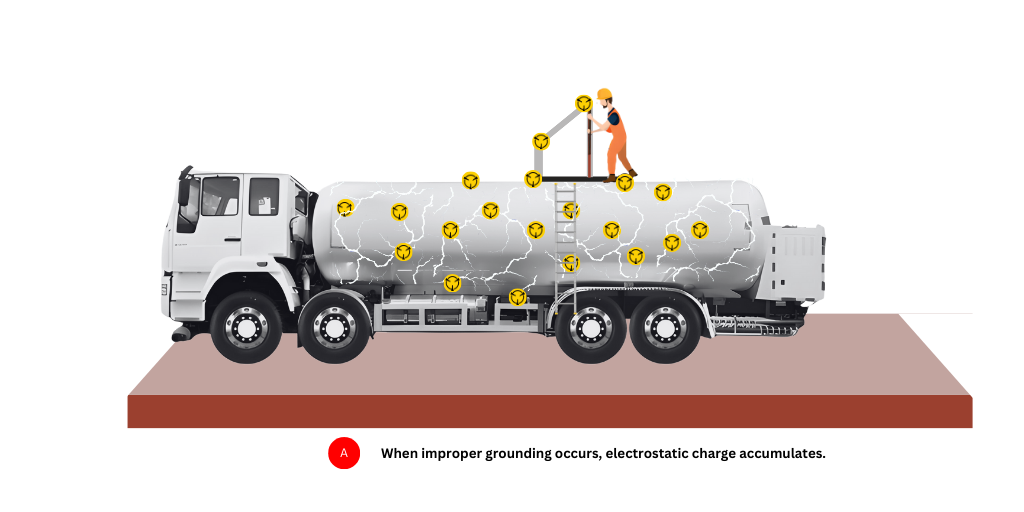

When a truck or tanker is loading or unloading and not adequately grounded, the flow of the product to or from the truck will cause static electricity to build up around the vehicle.

The increase in static electricity will also cause an increase in voltage around the vehicle. A certain amount of voltage is needed to create a spark, so it is important that the vehicle never reaches a point where any spark can be produced since the surrounding area is considered hazardous.

Our electrostatic grounding tester equipment/systems ensure that this never happens and enable the customer to be in compliance with recommendations such as IEC 60079-32-1 (guidance on explosive atmospheres and electrostatic hazards).

Our electrostatic grounding tester equipment/systems incorporate advanced technology designed to mitigate the risk of static electricity buildup during fuel transfer operations. By effectively dissipating any accumulated charge, these systems prevent the possibility of sparks that could ignite flammable materials, ensuring the safety of both personnel and equipment. This meticulous attention to safety standards allows the ‘fuel truck grounding system’ to meet and exceed regulatory requirements, providing peace of mind for operators and stakeholders alike.

The IEC document actually recommends that an earthing cable be connected to the truck before opening man lids or connecting pipes and this earthing cable should provide a bonding resistance of 10 Ohms between the truck and the gantry’s designated earthing point. The earthing device should not be removed until all operations are complete. The monitoring system continuously measures the resistance between the truck and activates interlocks to prevent loading when the resistance is above 10 Ohms.

When engaging in material transfer processes, such as loading or unloading trucks or containers, the inherent movement can induce static electricity. To mitigate potential hazards, the utilization of precision tools like Elok’s electrostatic grounding tester becomes imperative. This device ensures the robust establishment of a grounding connection for the truck or container. Failure to adhere to proper grounding protocols may result in static discharge events, presenting a significant risk of fire or explosion within the operational environment.

When loading dry bulk or liquid products onto a vehicle (such as a truck or tanker), the movement of materials creates friction between the materials and the vehicle’s surface and this friction generates static electricity, resulting in an electrostatic charge building up on the surface of the vehicle.

The buildup of this electrostatic charge increases the risk of a static spark occurring, which could potentially act as an ignition source.

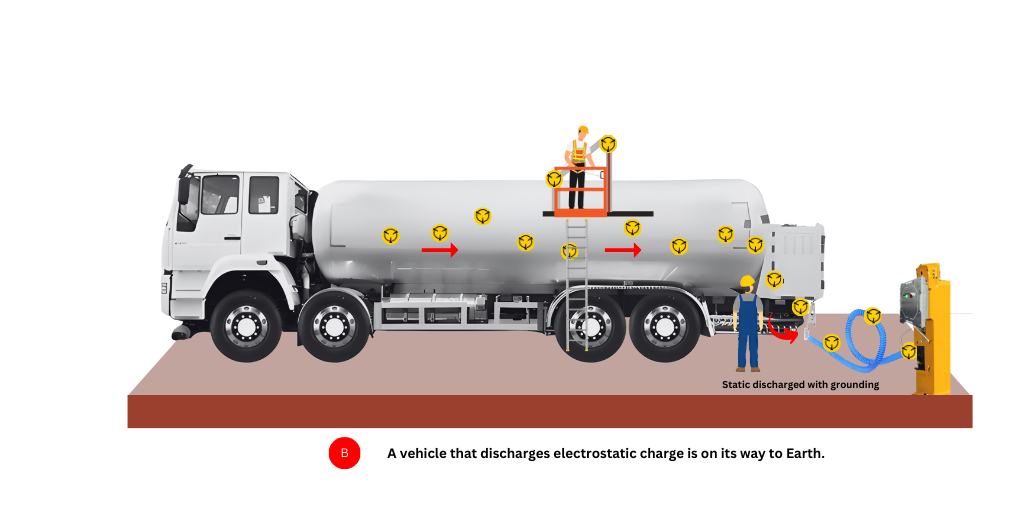

If the vehicle is properly grounded, it means that there is a conductive path from the vehicle to the earth and if the vehicle is grounded, the electrostatic charge on its surface has a pathway to dissipate into the ground.

Grounding the vehicle effectively prevents the electrostatic charge from accumulating to dangerous levels because any excess charge is safely discharged into the earth.

Proper grounding of vehicles during the loading process is crucial for safety. It prevents the accumulation of static electricity on the vehicle’s surface, reducing the risk of static sparks that could potentially cause ignition when handling dry bulk or liquid products. Grounding provides a safe pathway for the electrostatic charge to dissipate harmlessly into the ground, mitigating the risk of accidents or fires.

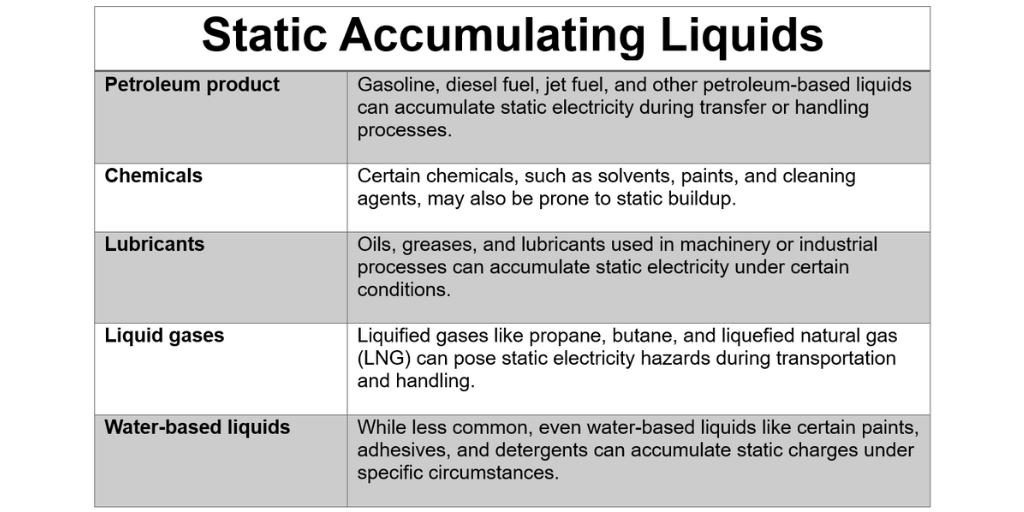

Static accumulating liquids are substances that have a tendency to accumulate static electricity when they flow or move.

Some common examples include:

Proper precautions, including the use of electrostatic grounding systems, are essential when handling these substances to mitigate the risk of static electricity-related incidents.

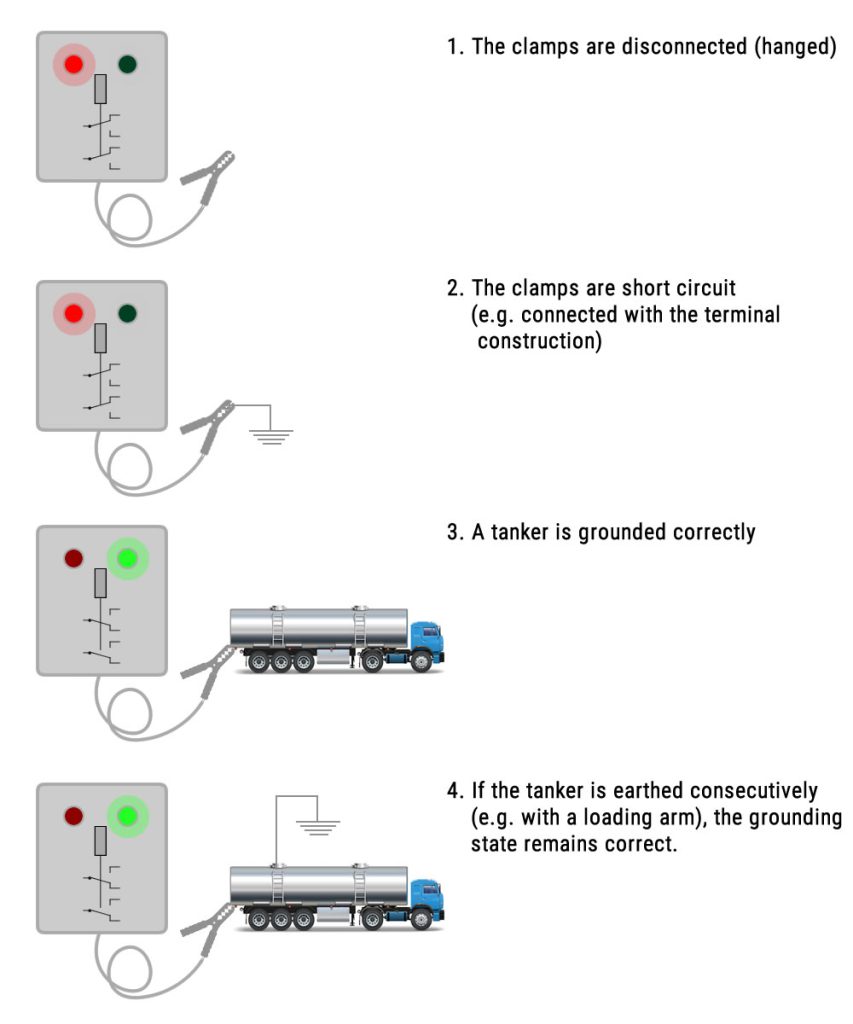

The Grounding Testers will ensure that everything is in place (safe) before unloading or loading. This means that it is necessary to have the grounding system connected to the tank and chassis of the truck, that the system is connected to true earth and that the resistance between the truck and the verified earth ground does not exceed 10 Ohms.

When the grounding clamp is attached to the truck (at the designated clamping point) the Grounding Tester electronics begin to measure the electrical signals to ensure that the clamps are connected to the truck.

This safety feature guarantees that the clamp is not being connected to the other parts of the truck which are isolated from the tank. In addition, the Grounding Tester electronics will ensure that it is connected to a true earth itself through its grounding rod.

The integrity/effectiveness of the grounding rod can be affected somewhat by moisture and temperature so the grounding tester also ensures that the resistance of the ground rod to the earth is low enough for loading/unloading operations to begin.

When it is safe to operate, the Grounding Tester confirms (by a Green Light) that the truck connection to the ground does not exceed 10 Ohms. The interlock mechanism (volt free contacts) will be activated (to automatically stop operations) if the grounding tester detects a rise in resistance of more than 10 Ohms.

In this way , the Grounding Testers ensure that sparking will never occur during product transfer and that personnel and assets are not at risk.

Shown are two Elok electrostatic grounding testers in operation.

Red light indicates a no go condition while the green light means it is safe to operate (load or unload)

Note: The Elok electrostatic grounder testers are not limited to tank truck loading/unloading applications. In fact, they are important in other applications where there is a possible ignition source (due to static electricity) in areas where there are flammable gases and dust.

There are a wide range of industries where this becomes applicable where certain authorities mandate that bonding and grounding is necessary. These might include butane tankers, condensate transport, ethanol, propane and other highly flammable chemicals and petrochemicals bound for refineries, tank farms, storage facilities and downstream industrial plants.

Elok as a manufacturer and trusted supplier can assist your organisation in helping to achieve the compliance needed to operate safely in these applications, especially when flammable liquids are being dispensed, transferred, mixed or loaded from one vessel to another.

Other typical/possible applications might include:

Elok Asia is an innovative solutions provider that has developed many products since it’s inception. If you require further review of your ideas, concepts and applications, please do not hesitate to contact us for further discussion.

Are Fuel Truck Grounding (FTG) Systems in common usage by all hazardous material transportation companies ?

Most companies who conduct thorough HSSEQ safety audits (transportation and loading/unloading of hazardous material by road and rail tankers) will incorporate these units as a standard operating procedure to ensure they are in compliance.

It is expensive to install a tanker earthing system for tanker loading and unloading?

It is not expensive to purchase our Ex certified tanker earthing systems when considering that they are going to be an additional safety assurance to ensuring that flammable products are less likely to ignite with proper earthing systems for fuel trucks. A quality earthing product will provide a higher safety level for the fleet in operation.

What is the best definition of Earthing a truck if we are to convince management needs to implement this.

Road Tankers transport chemicals, fuel and ignitable solids which can ignite and combust when sparks come into contact with them. If the possibility of static electricity is minimized as best as possible, then the management do not have to worry too much about the electrical charges accumulating in the fuel/chemical tanker when on the road. Some insurance companies have now made it an essential installation for preventing a fire or explosion by ensuring that everything or most everything is non-sparking during fueling or refueling.

Who is making sure that fuel tankers are wired to the earth ground?

Almost all large multi-nationals, oil and gas and petrochemical companies see this as a mandatory practice. However, the system in place might vary according to polices and location. The automatic system by Elok-Asia has become a popular method ensuring the most fool proof design.

Are there many parts to the Tank Truck earthing system?

No, the system is minimized and as uncomplicated as possible. Making things simple to use and understand is a part of good explosionproof strategy.

Do Fuel Truck Earthing systems require or have ATEX certification ?

All Elok systems are certified to ATEX Zone 1. Before installing any system, it is important for all personnel responsible for the installation of the loading unloading project(s) to ensure that every component and moving part of the system is in compliance.

Can we purchase a test unit at a reduce cost to try out first?

Yes! Once the earthing concept has been adopted , the operator can install a test/trial unit to affix to an earthing point on the truck body. Once the earthing procedure is defined and understood by all parties responsible, a test can be carried out to simulate and train the drivers to understand that the red light means that it is not properly earth, either a poor connection, cable break or something needs to be corrected prior to the pumping of flammable liquids, or solid(s) are initiated.

Do you provide third party inspectors to inspect the truck earthing system?

We do not provide this service but can if required recommend companies willing to provide inspection after installation. Our earthing products and grounding test systems are all ATEX certified, so it is important to follow the mandates stipulated by the ATEX authorities before proceeding to operate anything in a hazardous environment such as Zone 1.

Who is using the Earthing Test Grounding equipment in their tank farms and fueling refueling stations for fuel tankers?

A significant number of oil and gas companies utilize this earthing technology as standard practice. Contact us for more information if needed.

60 Kaki Bukit Place #01-12 Eunos TechPark

Singapore, SG 415979 Singapore

Telephone: +65-6748 9091

Email:info@elok-asia.com